HINEW electric co., LTD., a fuse holder manufacturer in China, has compiled some common knowledge about fuses. Please take 5 minutes to browse:

What is a fuse and what does it do?

A fuse is also known as a fuse and is defined by the IEC127 standard as a “fuse-link”.It is an electrical element installed in the circuit to ensure the safe operation of the circuit.

The function of the fuse is: when the circuit failure or abnormal, accompanied by the current rising, and the increased current may damage some important components or valuable components in the circuit, may also burn the circuit and even cause a fire.If the correct placement of the fuse in the circuit, so, the fuse will be in the current abnormal rise to a certain height and a certain time, their own fuse cut off the current, so as to protect the safe operation of the circuit.

The first fuse was invented by Edison more than 100 years ago. It was originally used to protect the expensive incandescent light bulb because it was very valuable at a time when the industrial technology was underdeveloped.

How does a fuse work?

We all know that when an electric current flows through a conductor, the conductor will be hot because of its resistance.And calorific value follows this formula: Q=0.24I2RT;Where Q is calorific value, 0.24 is a constant, I is the current flowing through the conductor, R is the resistance of the conductor, and T is the time of the current flowing through the conductor.According to this formula, we can see the simple working principle of the fuse.

When the material and shape of the fuse are determined, the resistance R is relatively determined (regardless of its resistance temperature coefficient).When an electric current flows through it, it heats up, and as time goes on it heats up.The current and resistance determine the rate at which heat is generated, and the construction and condition of the fuse determine the rate at which heat is dissipated. If the rate at which heat is generated is less than the rate at which heat is dissipated, the fuse will not blow.If the rate at which heat is produced is equal to the rate at which heat is dissipated, it will not fuse for a considerable time.

If the rate at which heat is produced is greater than the rate at which it is dissipated, then more and more heat will be produced.And because it has a certain specific heat and mass, the increase of its heat is shown in the rise in temperature, when the temperature rises to the fuse melting point above the fuse fuse.This is how a fuse works.

It should be known from this principle that when designing and manufacturing fuses, you must carefully study the physical properties of the materials you select and ensure that they have the same geometric dimensions.These factors play an important role in the normal operation of the fuse.Also, when you use it, make sure you install it correctly.

What is the configuration of the fuse?What effect does each have?What are your requirements?

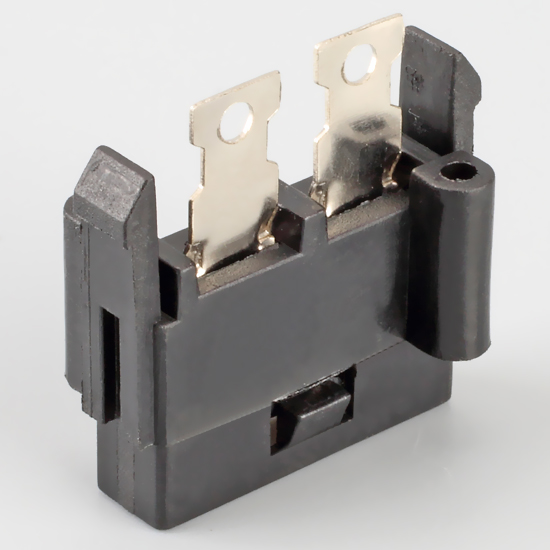

General fuse is composed of three parts: one is the melt part, it is the core of the fuse, fuse plays the role of cutting off the current, the same class, the same specification fuse melt, material should be the same, geometric size should be the same, resistance value as small as possible and consistent, the most important is the fuse characteristics to be consistent;

The second is the electrode part, usually has two, it is the melt and the circuit connection important part, it must have the good conductivity, should not produce the obvious installation contact resistance;

Part three is stents, the fuse melts is generally fine soft, the role of stents is to melt and make three parts fixed rigid overall ease of installation, use, it must have good mechanical strength, insulation, heat resistance and flame retardant, in use should not produce the phenomenon such as fracture, deformation, combustion and short circuit;

Power circuit and power equipment used by the fuse, not only has the three sections of the general fuse, and arcing device, not only because this kind of fuse protection circuit working current is larger, and when the melt occurs when the voltage at the ends of the fuse is very high, often appear the melt has melted (fuse) have even vaporizing, but current is not cut off, the reason is that at the moment of fusing under the effect of voltage and current, the fuse of the pull arc occur between two electrodes.The arcing device must have strong insulation and good thermal conductivity, and be electronegative.Quartz sand is a commonly used arc extinguishing material.

Additional, still have a few fuse to have fuse to indicate a device, its action is when fuse action (fuse is broken) hind its itself produces certain exterior change, be discovered easily by maintenance personnel, for example: give off light, change color, pop-up solid indicator.

What are the types of fuses?

According to the protection form, can be divided into: overcurrent protection and overheat protection.The fuse used for overcurrent protection is commonly known as a fuse (also known as current limiting fuse).The fuse used for overheating protection is commonly referred to as a “temperature fuse”.Temperature fuse is divided into low melting point alloy shape and temperature trigger shape memory alloy shape, etc.It responds to the temperature rise of the electrical appliance, regardless of the working current of the circuit.It works differently from a current limiting fuse.

By use range cent, can divide into: electric power fuse, machine tool fuse, electric appliance instrument fuse (electron fuse), automobile fuse.

According to the volume, can be divided into: large, medium, small and micro.

According to rated voltage, can be divided into: high voltage fuse, low voltage fuse and safety voltage fuse.

By cent break ability cent, can be divided for: high, low cent breaks ability fuse.

By the shape, can be divided into: flat head tubular fuse (can be divided into internal welding fuse and external welding fuse), pointed tubular fuse, guild-blade type fuse, screw type fuse, insert type fuse, flat type fuse, wrapped type fuse, SMD type fuse.

By fuse speed cent, can divide into: especially slow fuse (express with TT commonly), slow fuse (express with T commonly), medium fuse (express with M commonly), quick fuse (express with F commonly), especially fast fuse (express with FF commonly).

According to the standard, can be divided into: European standard fuse, American standard fuse, Japanese standard fuse.

What about slow fuses?

A slow fuse, also known as a delay fuse, has a delay characteristic that allows it to remain intact in the presence of a non-fault pulse current in the circuit, providing protection against prolonged overloading.

Some circuits have a current that is several times greater than the normal operating current at the moment of switching. Although this peak current is very high, it appears for a short time. We call it impulse current or impulse current or inrush current.

Common fuse cannot bear this kind of current, if what use in such circuit is common fuse, be afraid cannot start normally, if use the fuse of bigger specification, so when circuit overload cannot get protection again.

The melt of the delay fuse is specially processed, it has the function of absorbing energy, adjusting the energy absorption amount can make it can resist the impact current and provide protection against overload.Delay characteristics are specified in the standard. If the specified characteristics of the standard do not meet your requirements, you can contact the manufacturer for solution.

Is the fuse rated current the current that causes the fuse to blow?

It isn’t.Should regard it as the nominal of a kind of specification only, and the current that flows fuse is big what kind of degree, when fuse is broken this has detailed regulation to it in fuse product standard, because of the standard different and regulation differs somewhat.

A fuse has a “fuse factor” greater than “1″ (typically between 1.1 and 1.5), which is the ratio of “conventional non-fuse current” to “rated current”.It can be seen that even if the current flowing through the fuse is greater than its rated current and does not exceed the conventional non-fusing current, the fuse should not fuse.

How to understand the rated fuse voltage?

Whether a fuse is blown depends on the current flowing through it, independent of the working voltage of the circuit.The rated voltage of the fuse is put forward from the Angle of safe use fuse.This means that the fuse can only be installed in the operating voltage is less than or equal to the rated fuse voltage circuit.Only in this way can the fuse work safely and effectively, otherwise, when the fuse is blown will appear continuous arc and voltage breakdown and harm the circuit phenomenon.

What does the voltage drop of the fuse say?

The voltage drop of the fuse is the voltage drop at both ends of the fuse under the rated current condition.It reflects the internal resistance of the fuse and its value should not be too large.If the internal resistance (voltage drop) too large fuse installed in the circuit, it will affect the circuit system parameters, so that the circuit can not work properly.The standard specifies not only the upper limit of voltage drop, but also its consistency.

What is the point of studying the temperature rise of a fuse?

The temperature rise of fuse is to point to the value that when 1.1 times (110%) rated current flows through fuse, the temperature of fuse rises in value, the value that measures temperature to subtract environmental temperature namely.The UL standard sets the upper limit at 75Co.Because fuse melt is more sensitive to temperature, under the action of a certain high temperature for a long time, its melting point and impedance will change, which will affect the accuracy of the fuse.This is commonly referred to as a blown fuse.The aging fuse is very dangerous to use in the circuit, so we should pay attention to the temperature rise of the fuse when making and using it.In the same way, we should note that even if a fuse has not blown after a long time of use, it may be worn out and it is best to replace it.

What does the breaking power of a fuse mean?

When applied to a fuse by a current between the conventional non-fusing current and the rated breaking capacity specified in the relevant standards, the fuse shall operate satisfactorily and not endanger the surrounding environment.Fuse is placed in the circuit of the expected fault current must be less than the standard provisions of the rated breaking capacity current, otherwise, when the fault fuse fuse fuse will appear continuous arc, ignition, fuse burn out, together with the contact piece melting, fuse mark can not identify and other phenomena.Of course, the cent of inferior fuse is broken the requirement that the ability does not reach standard to stipulate, can produce afore-mentioned harm likewise when using.and does not exceed the conventional non-fusing current, the fuse should not fuse.

Post time: Oct-31-2019