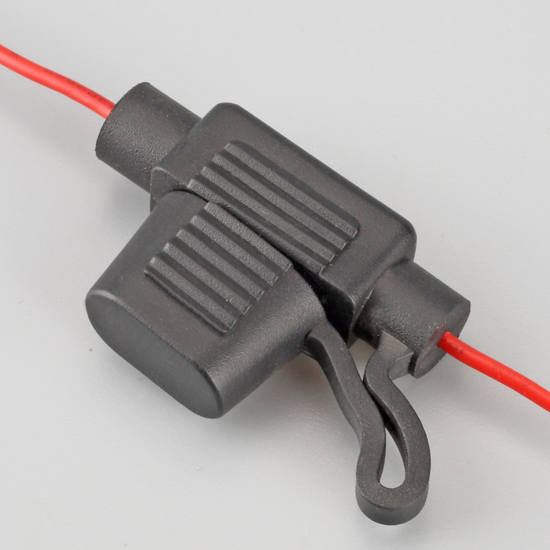

Requirements and characteristics of fuse holders?

The most important standards for fuse-holders, which specify requirements, characteristics and testing methods are:

IEC-publication 257 (1968) and Amendment no. 2 to this publication dated January 1989.

UL-standard no. 512.

Both standards show considerable differences. In the case of fuse links, compliance with the UL-standard does not usually mean that the fuse-holder under consideration meets IEC-requirements and vice versa. In the following, some of the most important differences between the two standards will be indicated.

From an application point of view, a fuse-holder is characterized by the features discussed in the previous section by its rated values for voltage, current, and accepted power. Considerable differences exist between the IEC and the UL standards regarding the rated current of a fuse-holder. According to IEC 257, the rated current is determined by the rated accepted power of a fuse-holder. The rated accepted power is, according to IEC 257, “A stated value of power dissipation (of a fuse link) which a fuse-base or fuse-holder can accept under prescribed conditions of use and behavior.” Rated values of accepted power are 1.6 W, 2.5 W or 4 W. For example, it means that at a power dissipation of 4 W (by a fuse link placed in the fuseholder) temperatures of the fuse-holder should not exceed certain limit values as specified in the standard. This rated accepted power determines the rated current. Basically, this means that the rated current is not a fixed value. As an example, let us assume that the rated accepted power of a fuse-holder is 2.5 W.

Quick-acting fuse links specified in IEC 127 part 2, standard sheet II, have power dissipations which do not exceed 2.5 W (see table 4.3). For these fuse types the fuse-holder under consideration is able to accept all fuse ratings up till 6.3 A of this type of fuse links. High breaking capacity fuses specified in IEC 127, part 2 standard sheet I, however, show power dissipations up to 4 W at highest ratings (see table 4.3). Fuse links of this type with rated currents of max. 1 A show a maximum power dissipation of 2.5 W or less. This means that only fuses of this type with a rated current of 1 A maximum can be used in combination with the fuse-holder under consideration.

UL measures the temperature rise of a fuse-holder using a solid copper dummy fuse. In this case the fuse resistance is negligible. Most heat comes from the contact resistance of the clips; the current is turned up till a certain temperature rise occurs, and this current value is considered to be the rated current of the fuse-holder. However, we have no heat generated from the fuse and the copper dummy fuse acts as a heatsink, extracting heat from the clip area much better than a fuse would do.

It might well be that in this way a current rating of 20 A is defined, whereas following IEC-requirements the rated accepted power is 2.5 W. This means that for certain types of fuse links the current rating is limited to 1 A.

Roughly speaking, a UL rated fuse-holder should be run at no more than 30% of its rating in a real life application. In the case of panel-mounted fuse-holders it may be safer to derate even further due to their enclosed nature and the tendency to use push-on connectors which also have a contributory contact resistance. A fuse link in a panel-mounted fuse-holder should be downrated by 5 or 10%, due to the poorer heat transfer properties in this arrangement.

The voltage rating of a fuse-holder is governed by a number of design aspects like the distance between terminals, creepage distances and minimum clearance distances. Further aspects of insulation coordination as specified in IEC 664/664A have an influence on the voltage rating. In general a fuse-holder will perform satisfactory at any voltage equal to or lower than the rated voltage. As a remark the existing standard IEC 257 will be replaced by a fully revised standard, viz IEC 127, part 6.

Post time: Aug-16-2018